Innovative Circular Economy: PET Bottles and Cups in a Closed Recycling Loop

29. September 2025

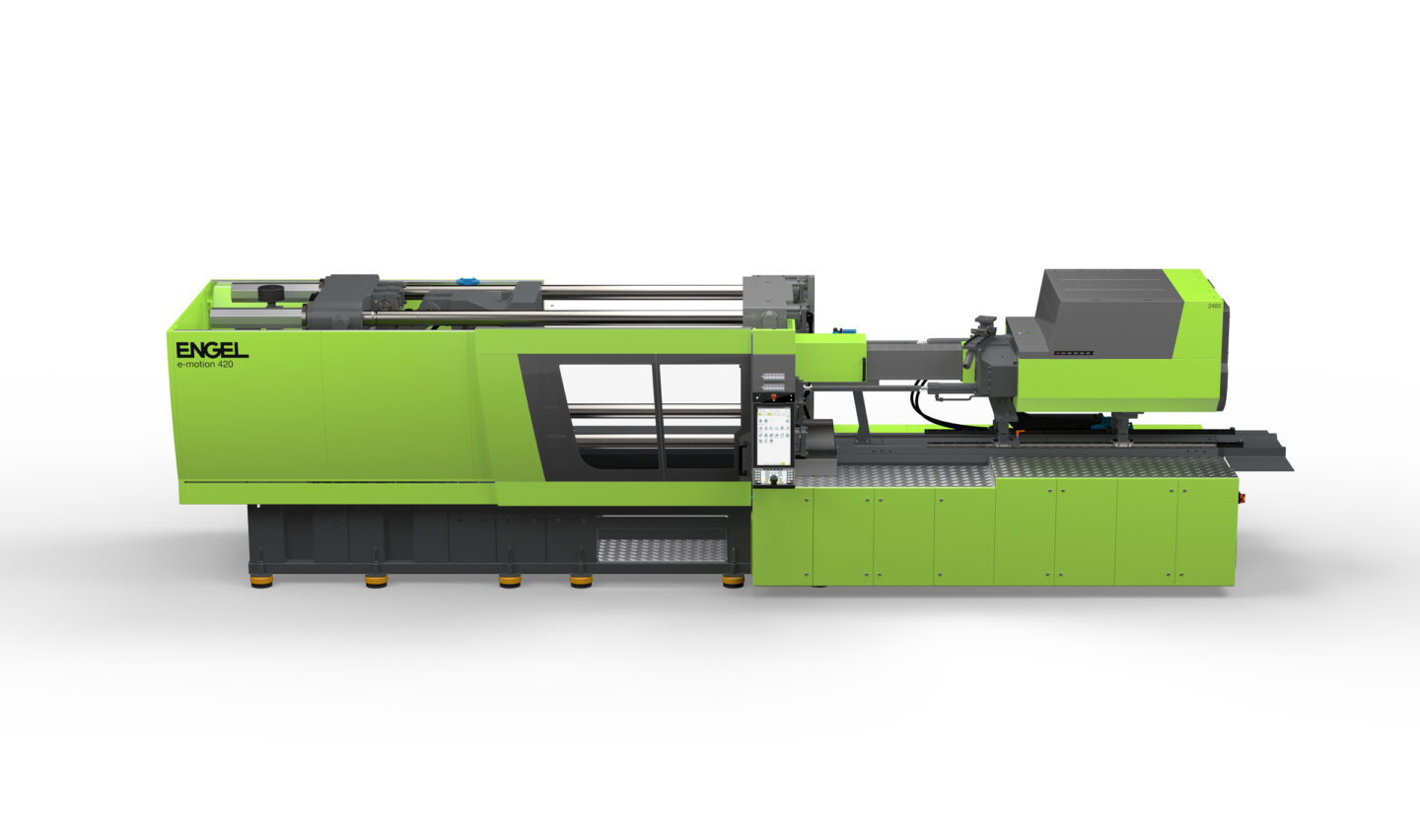

NGR & ENGEL showcase the closed loop in thin-wall injection molding—including sorting-friendly IML.

At K 2025, PET cups with 30% recycled content produced on an NGR LSP® line will be manufactured in a high-performance injection moulding machine with in-mold labeling from ENGEL!

Beverage industry focuses on resource conservation and recycling

The beverage industry is under increasing pressure to produce more resource-efficiently and make packaging more sustainable. A decisive step in this direction is closed recycling loops for PET bottles and PET cups. This article explains how this process works and highlights the innovations currently shaping the industry.

“Best practice” – the PET bottle

Recycled PET materials are in no way inferior to virgin PET and can be used again to produce preforms. In this recycling loop, NGR’s LSP® technology is an important partner in the preparation and pelletizing of rPET. The forward-looking liquid-state polycondensation (LSP®) technology purifies PET directly in the melt phase, achieving the highest purity. This is how raw material for absolutely safe food packaging is produced with the lowest energy consumption.

At the beginning of the loop is the PET bottle, which is formed from preforms by blow molding immediately before filling into the desired shape. After filling, capping, and labeling, the bottles reach the consumer via retail. After consumption, the empty bottles are returned through established collection systems.

This is where the actual recycling process begins: PET bottles are freed from caps and labels and sorted by color, then shredded and washed. The result is pure, clean PET flakes. These flakes are then melted and, in a special polycondensation process, restored to the target viscosity and fully decontaminated. This creates high-quality rPET pellets.

Innovation: food-grade PET cups with recycled content

A significant advance is the first-ever integration of 30% bottle regranulate into the production of PET yogurt cups. These cups are produced by injection molding, where the high-quality virgin pellets are blended with recycled material from bottles. Here, Novapet’s know-how comes into play, ensuring consistent quality of the virgin PET.

Implementation in the packaging sector would not be possible without the commitment of experienced partners such as Polytainers, specialists in the manufacture of high-quality food packaging and Plastisud, whose stack molds for thin-wall cups and rPET set international standards. An innovative feature: labels are placed directly in the mold during injection molding without adhesive, greatly simplifying separation and subsequent recycling. The fully integrated implementation is ensured by the ENGEL Group, which develops innovative production cells where precision, energy efficiency, and sustainability go hand in hand.

Closing the loop

After filling and sealing, the PET cups reach retail and, finally, the consumer closes the recycling loop. Here too, after use, the cups are returned through dedicated collection systems. The collected cups are shredded, with the labels detaching easily and being separated without difficulty. Thus, the cup not only goes through its own recycling loop but also integrates seamlessly into the bottle material stream. This return ensures that no raw material source is lost to the PET loop.

Conclusion: circular economy as a model for the future

This example demonstrates that with modern recycling processes, PET bottles and PET cups alike can be recycled resource-efficiently and returned to the loop. The prerequisite remains comprehensive and pure-grade collection. In this way, the beverage industry—together with dedicated partners in technology development, material production, and industrial manufacturing—can make an important contribution to the circular economy while meeting EU packaging regulations—a win for both the environment and society.

To produce PET yogurt cups, 30% bottle regrind was added—making it possible, for the first time, to produce food-grade cups with the required recycled content without additional additives.

The loop for the PET cup is as follows: the PET cup is produced by injection molding; the pellets from Novapet are mixed with 30% bottle pellets, and the cups are molded. The labels are placed directly in the cup during molding so that they are bonded without any additional adhesive. The cups are filled with yogurt and sealed. Via retailers they are brought to market. After consumption, the cups are collected and sorted. They are shredded in a mill, during which the labels come off and can thus be separated easily. The material is then fed at an appropriate point into the bottle processing stream in the washing plant. The amount thus added is processed together with bottle regrind into bottle regranulate.

In the first step, raw material is withdrawn from the bottle; however, this cup can be returned to the bottle in the recycling process. All legal requirements are met. No raw material source is lost, since cups can be returned to the bottle stream—provided appropriate sorting is ensured.