E:GRAN

The compact repelletizing solution for any type of film

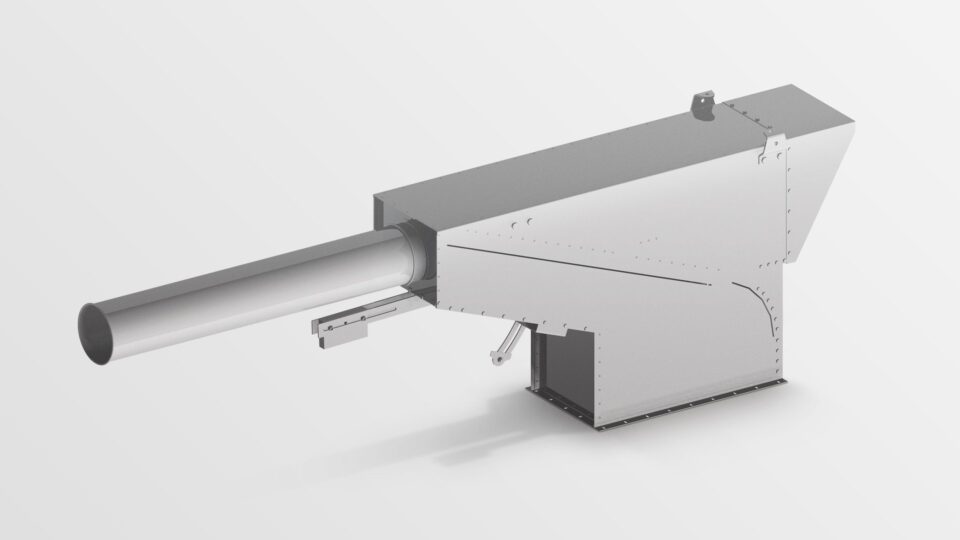

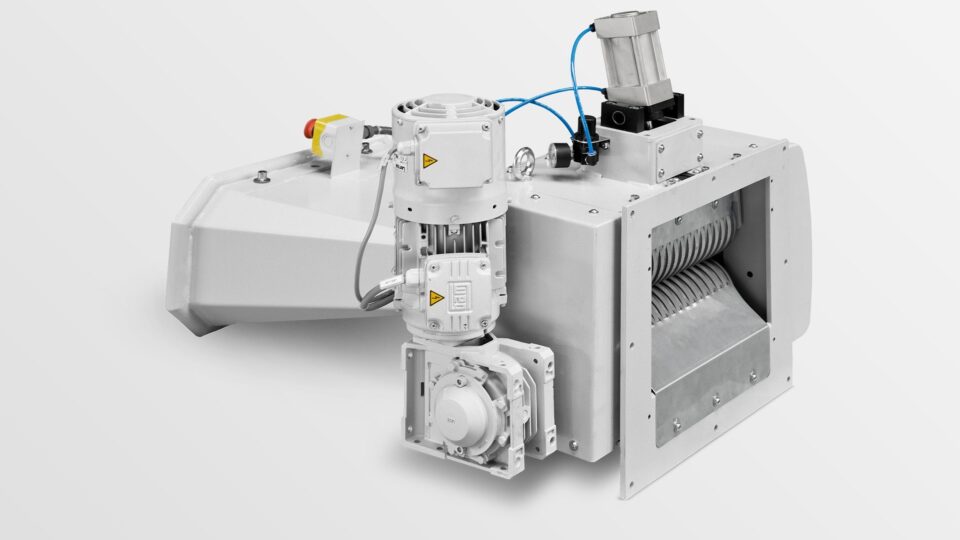

A space-saving design, an energy-efficient drive and simple, intuitive operation. These are all features of the plastic recycling plant equipment E:GRAN, the re-processing technology for thermoplastic film edge trims and roll scraps.

Description

Whether it‘s being used as a stand-alone solution or integrated with a film pro- duction process, E:GRAN stands out for its ideal in-feed thanks to the innovative chopper/feeder design. The chopped film material is pre-compressed and fed directly to the extruder. This makes it possible to carry out highly economical and environmentally friendly zero-waste production (all production waste is fed back in). Innovative control concepts allow the plastic reprocessing machine E:GRAN to adapt to fluctuating edge trim amounts automatically – for maximum product quality.

What else makes E:GRAN great? Its process stability, its energy efficiency and its compact size make it stand out across the board. Its robustness allows it to operate 24/7/365 while ensuring precise and consistent output.

At a glance

- Effective film preparation

- Output rate up to 120 kg/h (270 lbs/h) depending on type

- Automatic adjustment of the extruder speed to fluctuating edge trim amounts

- Switching on and off by a single push button

- Clean, dust-free operation: The machine can even be installed in production halls

- One-step technology – without additional intermediate steps

* Output values for ldPE according to NGR company standard, depending on material and quality.

In addition, NGR provides all the equipment for conveying pellets such as blower, pipes, cyclones and much more.

Technology

The operating principle of E:GRAN

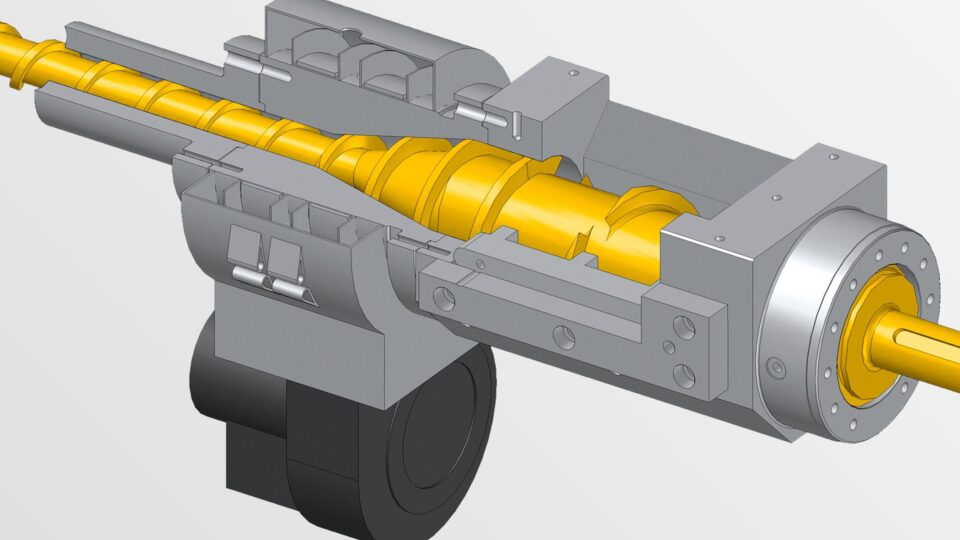

Plastic film and film edge trim are chopped directly in the extruder feed section. The conically shaped conveying area of the screw compresses the material as it enters the extruder.

In the extruder, the material is brought to a uniform melt temperature and subsequently pelletized.

The feed section (where the material is chopped), conveying area and the extruder all lie along a single shaft. The resulting design requires only one energy-efficient drive.

All the components are positioned in close proximity to prevent oxidation of the material and to make optimal use of heat from the chopping process.

All models in the E:GRAN series feature this patented chopper-feeder-extruder combination.

One-step-technology

In a single step process, the film edge trim is chopped directly in the extruder feed section and fed into the extruder.

High performance for a small space requirement

With its compact design, the system can be installed in areas of limited space and its versatility also allows it to be integrated at a later time in the main process.

One-button automatic On/Off control

The control system provides for smooth start-up of equipment components. Restart after unplanned shutdown in less than two minutes with full hopper and full extruder.

For automatic inline production

Automatic response to differences in quantity when processing edge trim ensures consistent pellet quality.

Extruder screw

Extruder screw

Specially developed for the challenges of recycling, the extruder screws provide optimum melt homogeneity and process material efficiently with minimal loss of physical properties.

Control unit

Control unit

All equipment functions from feeding to pelletizing are controlled automatically from the easy-to-read NGR touchscreen. Recipes are managed in the operator control unit, which increases traceability, provides ease of use, and ensures equipment parameters are set properly.

High-quality pellets

Pellet size

In addition to high quality, the uniform pellet size also provides for homogeneous mixture in new material. NGR thus plays an indirect role in ensuring consistent quality in the final product.

Add-Ons

Feed-in

Degassing

Pelletization

Filter

Test equipment

Feed-in

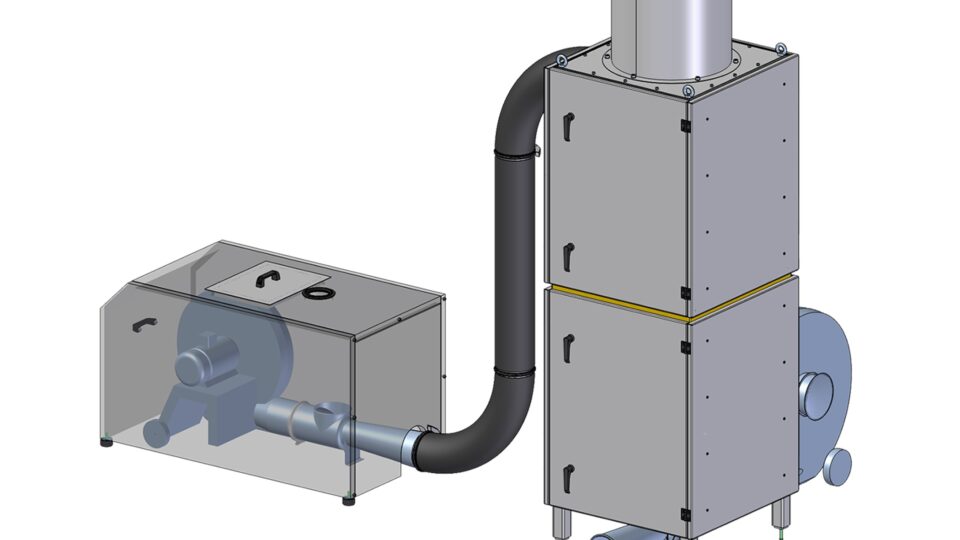

Air separator

Air Seperator

The air separator is used in the production process to continuously recycle film edge trim, which is fed pneumatically into the machine. With “inline operation,” further material handling is unnecessary, and the NGR recycling machine is now fully automated.

Roll feeder

Roll Feeder

With variable feed speed, roll scrap is treated in a process-controlled manner. The virtually unmanned machine is fed continuously. The roll feeder can be operated at the same time with other types of feeding (e.g. conveyor belt).

Degassing

Venting

Single venting

Designed for light printing and low humidity. The vacuum degassing system includes a vacuum pump and is connected to two venting ports on the extruder.

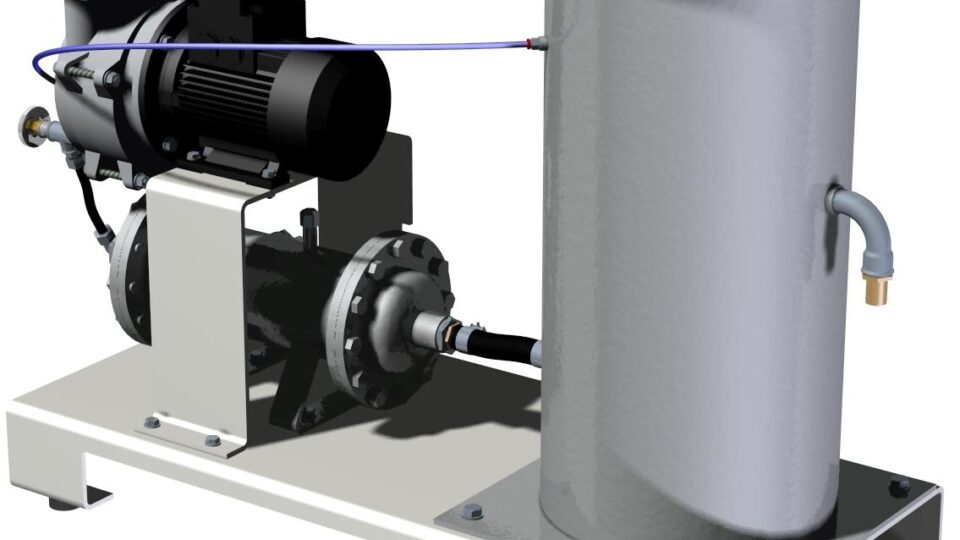

Vacuum pump with closed water circuit

Vacuum pump with closed water circuit

Each venting combination can be equipped with a closed water circuit. The fresh water consumption at the vacuum pump is thereby reduced significantly.

Pelletization

HD pelletizer

Hot-die Waterring Pelletizer (HD)

For thermoplastics with a higher viscosity. The melt exits through the wear-resistant die plate, and is knocked off by the pelletizer blades. The pellets cooled in the water ring are flushed out, dried in the centrifuge and discharged. By adjusting the blade pressure, pelletizer blades provide a long service life; replacement is quick and easy.

Hot die-air pelletizer

Hot die-air pelletizer

Specially designed for inline applications where water is not used. The melt exits through the wear-resistant die plate, and is knocked off by the pelletizer blades. The pellets are carried away in the air stream and cooled.

Filter

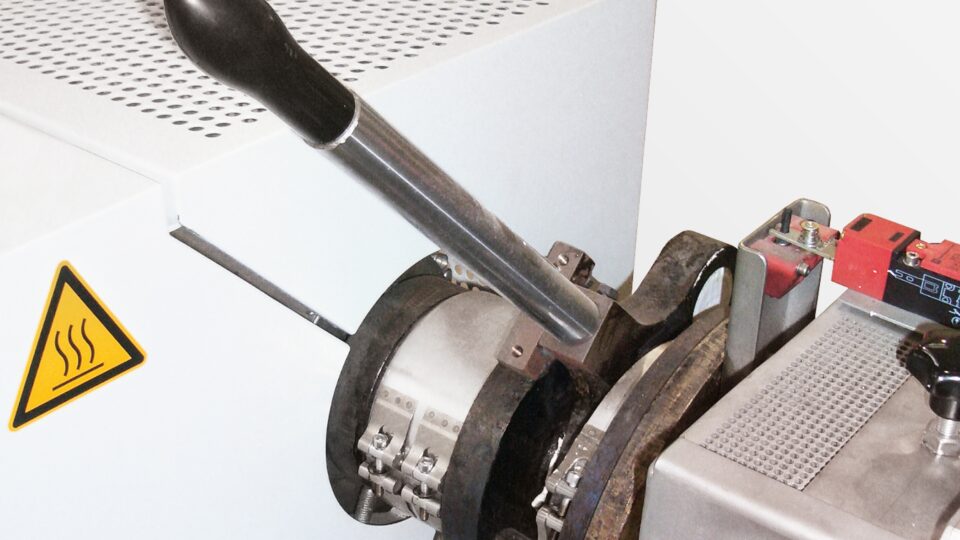

Manual screen changer

Manual screen changer

For clean, in-house production waste. Using the manual lever, two screens can be swung out alternately to allow for cleaning of the melt stream. The process is discontinuous, because the machine has to be switched off to change the screen.

Test equipment

Flow scale

Flow scale

The throughput scale is integrated in the machine control system and displays the current production output in kg/h (lbs/hr). The data can be logged in a BDE system.

Gallery

Images

Solid engineering, high-quality materials and precise execution ensure a long service life for equipment.

maintenance-friendly access to moveable parts allows you to quickly change material, efficiently disassemble and assemble wear and tear parts, and minimizes downtime.

Testimonials

NGR´s a very reliable piece of equipment helping us saving money by recycling our trims. One of the nicest things with this NGR is that you switch it on and forget about it, it just runs.

Jacques van Vuuren, General Manager

Gundle Plastics, South Africa

Our NGR Machines are performing well! One of these machines is a 2009 model and the other is a 2012. Neither has had new screws until recently. We decided to change out both screws with new ones from NGR. We are not only running trim but are also using to regrind using the feeder as well. We are looking forward to installing 2 more E:GRAN 50’s and also our Vented Recycling Line! We appreciate NGR and Adams Engineering for your continued support. Who knows what the future holds

Rick Gibson , Engineering Manager

Indevco, Texas

In our company,there are 3 NGR machines, E:GRAN and two S:GRAN which are taken at various times. These machines are easy to use. Production and Labor Safety in the forefront. The automation system of the machine has been selected from the brands that maintainers can easily reach. PLC and motor drives can be easily backed up. Operators can easily use the operator panel. And the service that NGR offers, is fully dependable and trustable. Thank you NGR for your excellent cooperation

Abdülaziz Aktaş, Factory Manager

Sekuro, Turkey

Success Stories E:GRAN

Support

Our all-round service – satisfaction included

Excellent technology calls for excellent service. Our 100% commitment to flawless service ensures maximal cost efficiency and minimal downtime.

Our services

- Service hubs for the fastest possible processing of all maintenance and repair work

- Spare parts centers for flexible responses to strong markets

- High spare parts availability thanks to particularly high stock levels in Europe and North America

- Worldwide extruder screw production for short-term production or repairs

- Starter and spare parts packages for every new machine

NGR Applications & Solutions

[5 MB]