Tradition Meets Innovation

6. October 2025

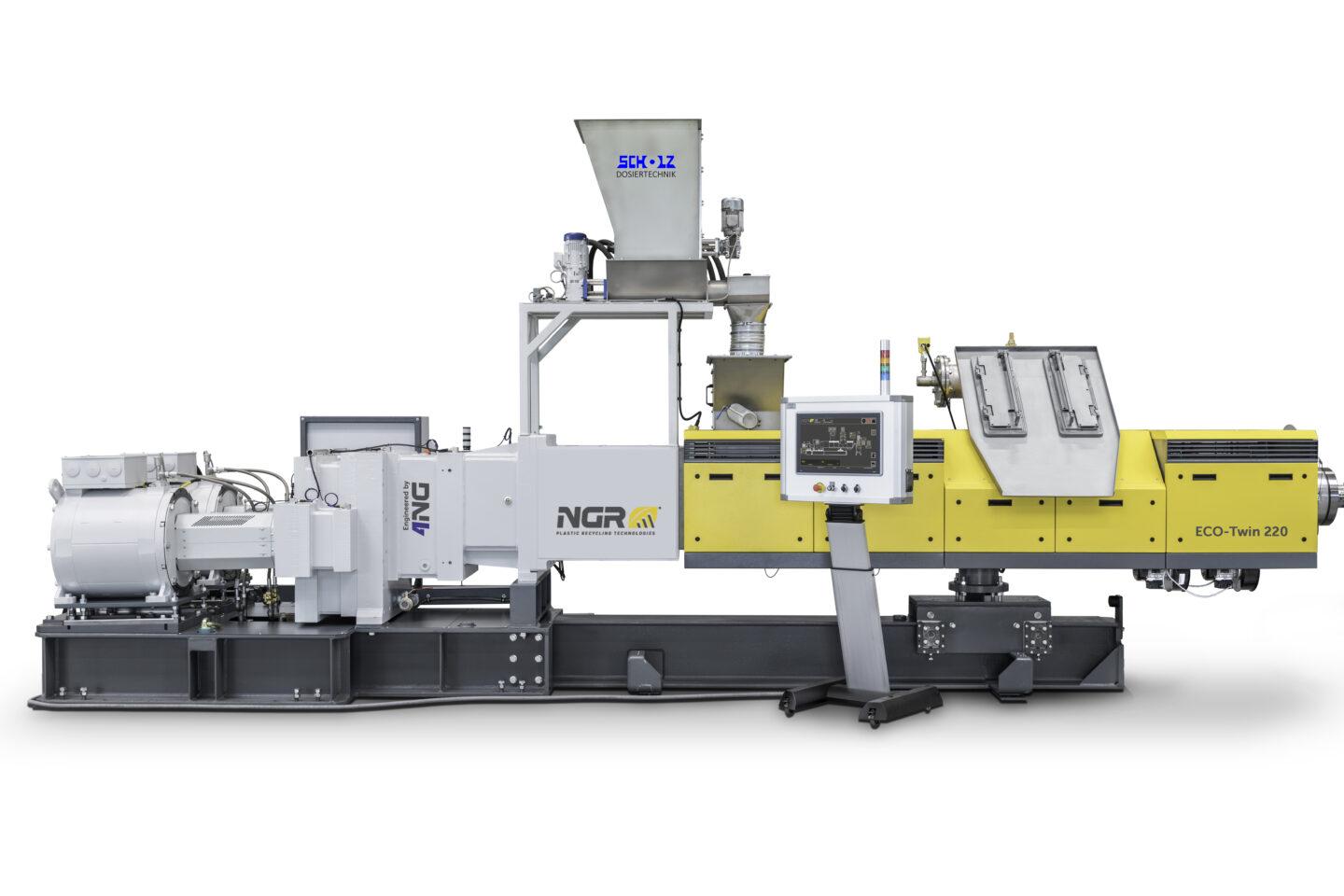

ECO-Twin Extruder – The Conical Co-Rotating Twin Screw 2.0

Next Generation Recycling Machines (NGR) presents the new ECO-Twin 220 – a conical co-rotating twin screw extruder that perfectly combines innovation and tradition. The extruder was developed by DI Günther Klammer together with an experienced team from 4NEXT Generation GmbH (4NG). 4NG consists of Günther Klammer, Stefan Lehner, Mario Strutzenberger, and Harald Engleder – all with many years of experience in engineering recycling machinery.

Günther Klammer, the mastermind behind 4NG, has already proven his creativity with more than 35 patents. With the development of the ECO-Twin extruder, he once again demonstrates his innovative strength. (Several technical features of the ECO-Twin technology are also patent-pending.)

“With the ECO-Twin, we are reaching a new level of efficiency in the recycling process,” says Günther Klammer. “The ECO-Twin extruder represents the next generation – a ‘Conical Co-Rotating Twin Screw 2.0’, combining proven principles with state-of-the-art drive and process technology. It gently processes plastics while setting new standards in energy consumption and throughput performance.”

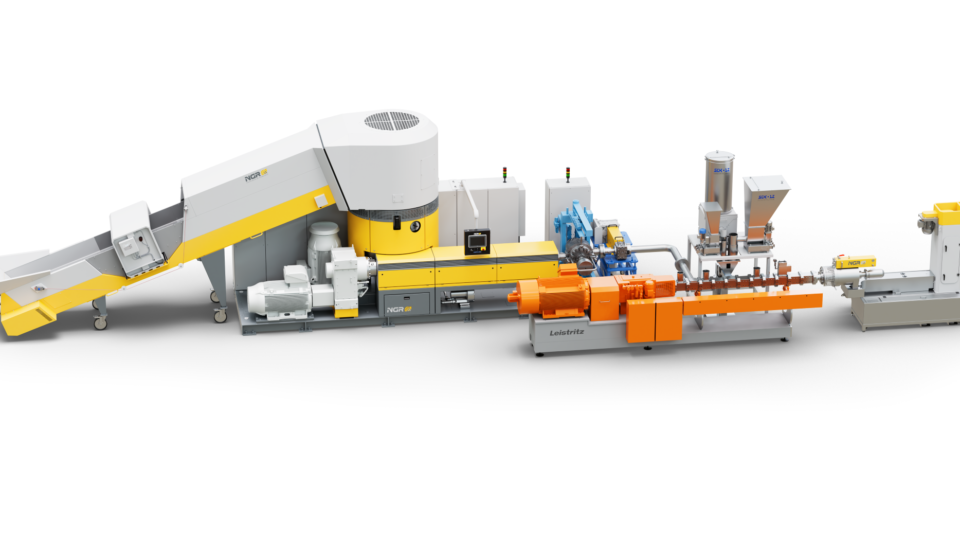

Outstanding Performance Especially in PET Processing

Conical co-rotating extruders have proven particularly effective in processing PET bottle flakes. The conical design ensures very low energy input during the melting of pre-dried flakes, allowing the extruder to operate almost adiabatically.

The screw geometry follows a natural physical principle: large surface areas and high circumferential speeds in the feed zone to introduce energy into the material, and smaller surfaces with lower speeds in the discharge zone to minimize friction and dissipation.

This makes the ECO-Twin the gentlest solution for processing low bulk density plastic regrind. The concept meets the physical and rheological demands placed on an extruder in an optimal way.

Drive Concept

The drive is based on a compact Beveloid- gearbox with conically shaped output gears. The axis spacing is designed to transmit exceptionally high torque – ideal for high power output at low rotational speeds. Robust spherical roller bearings reliably absorb high radial and axial forces.

The symmetrical design ensures uniform torsional and axial stiffness, keeping the screw clearances constant – a key advantage for process stability and product quality.

An optional monitoring system tracks oil condition, lubrication, cooling, speed, and vibrations in real time. This allows for precise and cost-effective maintenance planning. The targeted circulation lubrication requires only small amounts of oil, further reducing maintenance costs.

ECO-Twin 220 – Drive

Two high-performance synchronous motors enable a particularly compact drive layout. They also allow highly precise dosing control by accurately detecting torque fluctuations. As a result, the extruder operates with exceptional stability – delivering consistent energy input and high, precisely controllable throughput rates.

The Barrel

The barrel is connected to the gearbox via a coupling bell that effectively dampens mechanical vibrations, contributing to smooth operation. The screws are supported in the flange area, significantly increasing the extruder’s overall stability.

For maintenance, the barrel can be swiveled open on both sides – a space-saving solution that allows quick and easy screw removal. This is especially advantageous in systems producing semi-finished products such as films, where frequent product changes and high cleaning requirements are common.

Compact Design and High Performance

With a length of just 7.5 m, the ECO-Twin 220 is designed to be extremely space-efficient. With an installed power of 570 kW (2 × 285 kW), it achieves throughput rates of up to 4,000 kg/h. The maximum motorization of 650 kW (2 × 325 kW) enables throughput rates of up to 6,000 kg/h – ideal for high-performance applications in compact plant layouts.

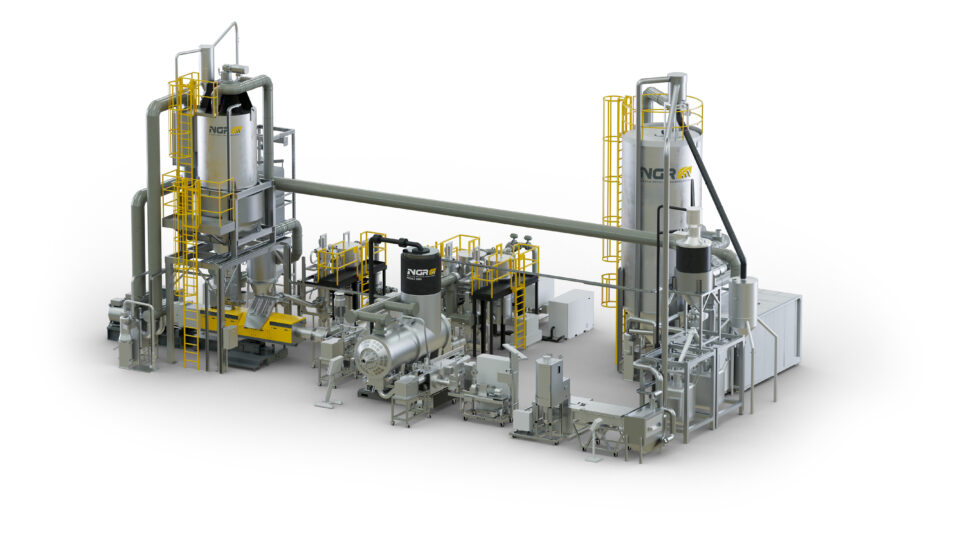

Premiere at K 2025

The ECO-Twin 220 was developed by 4NG (4Next Generation) – a member of the Next Generation Group. The innovative extruder technology will be presented to a broad professional audience for the first time at K 2025.