New X:GRAN DCU

6. October 2025

New feeding concept – sensational performance!

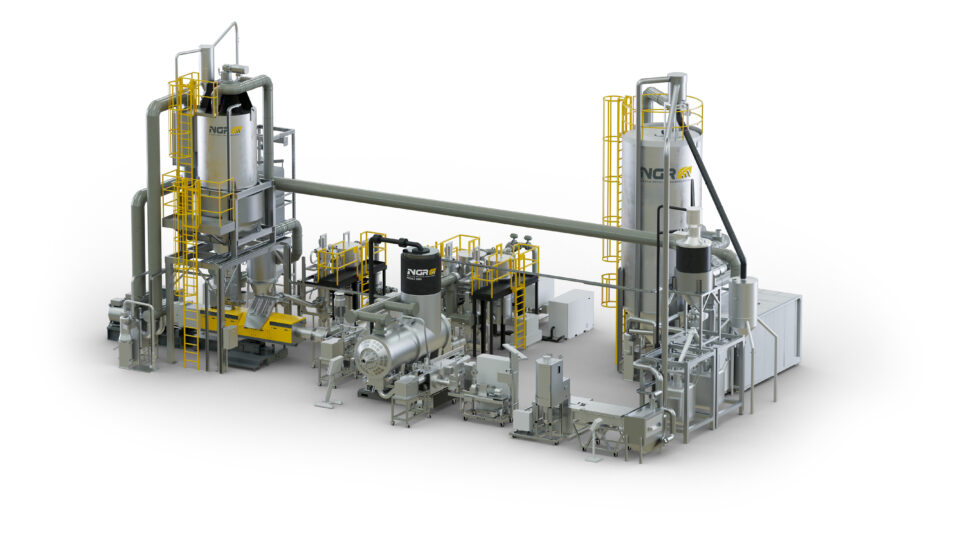

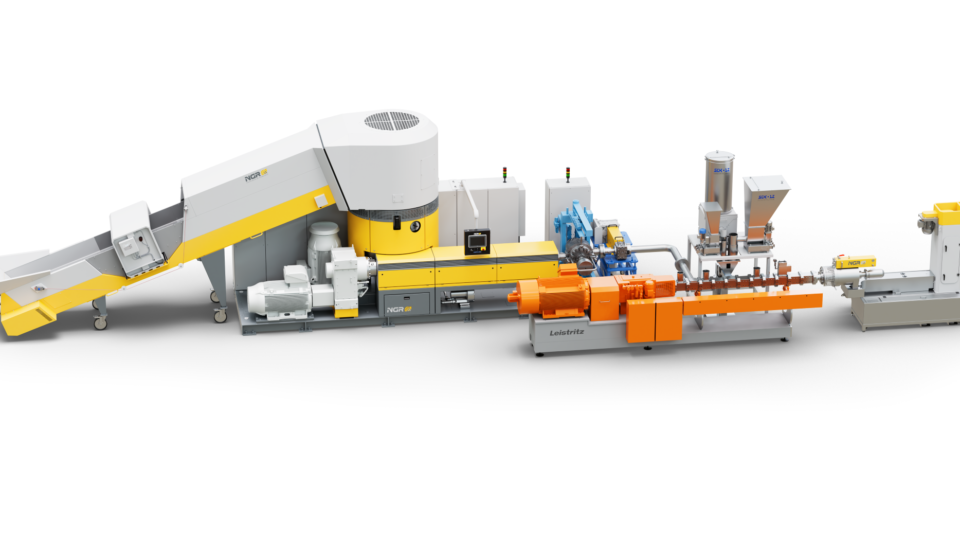

As part of the NXT: PLATFORM we have taken the next step in shredder-extruder technology with an entirely new concept, combining elements of our proven S:GRAN and X:GRAN, creating a hybrid solution, to deliver a sum greater than both parts. We call this a Dynamic Classifying Unit (DCU).

“We are very excited to bring this technology to market” says Creighton Varney, Product Manager of Post-Industrial Recycling at NGR. “It is a completely new concept, bringing all the benefits of our IP from the S:GRAN, and combining it with a twin screw, mechanical feeding solution”.

High quality size reduction

The X:GRAN DCU 145 utilizes a ‘Classification Unit’, comprising of two uniquely designed augers to accurately convey, mix, and meter the material to the downstream process. Using a variable speed shredder shaft, augers, and updated AUTO-PILOT controls, the level of size reduction is accurately controlled.

Pre-Venting, putting venting first.

Our cutting process can introduce varying levels of heat into the material. This is used, in conjunction with an air-flush system, to reduce the levels of residual moisture in the material before it enters the extrusion process.

Varney added, “With the patented design of the Classification Unit, and relationships between the feed components, we can control the level of cutting, generating an overcut of the material, but fully controlling the process, this gives a lot of advantages such as a level of pre-heating, higher densities, and a very stable feed to the extruder.”

Optimised form, stable process

The patented X:GRAN DCU 145, designed under the NXT: platform, eliminates dead spots in the process. This gives a very stable, homogeneous throughput, an ‘extrusion-friendly’ feed.

“The key to the process is a fundamentally sound mechanical design. Having a robust material flow means we do not have to use control systems to police every part of the process, it is inherently stable in its principal design” explained Varney.

Putting challenging materials first

Understanding the most difficult materials to re-process, ad delivering application-driven solutions to meet these needs, has always been a cornerstone of NGR’s philosophy. With the NXT:PLATFORM allowing a high level of modularity between our core component groups we have been able to engineer the X:GRAN DCU 145 with many proven components.

Varney concluded, “The X:GRAN DCU 145 has been a remarkable success in the test phase. Its ability to process every material that we have challenged it with shows just how important this development is to the future of our portfolio, and the wider industry”.