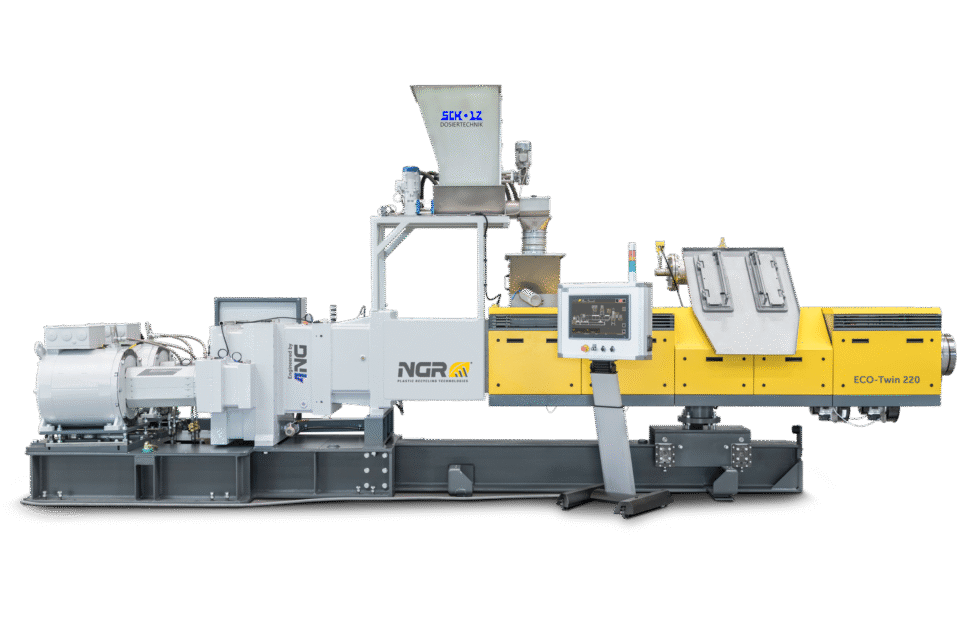

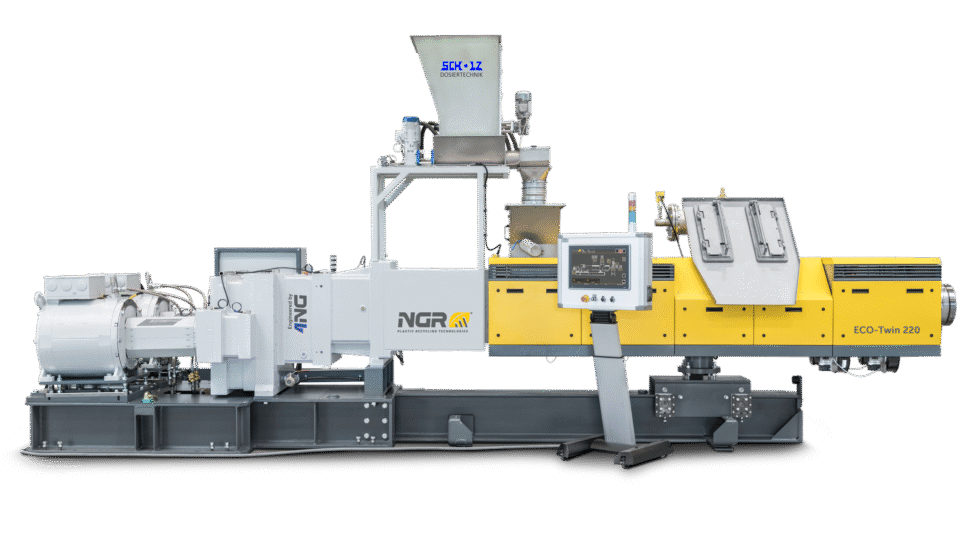

ECO-Twin 220

Efficiency in Perfection

The Conical Co-Rotator 2.0

Conical co-rotating extruders have proven particularly effective in processing regrind with low bulk density, such as PET bottle flakes. The conical design ensures very gentle melting of the pre-dried flakes while keeping the energy input remarkably low.

Description

With the conical, co-rotating ECO-Twin extruder, NGR sets new standards in the processing of PET regrind. Extremely low energy consumption, combined with a very gentle melting process and highly effective melt degassing, makes this extruder the embodiment of efficiency. The concept fulfills the physical and rheological requirements of an extruder perfectly.

The drive consists of an extremely robust and compact beveloid gearbox, which can optionally be equipped with

a monitoring system. With this constant monitoring,

necessary maintenance cycles can be precisely planned. The ECO-Twin 220, currently used in LSP systems with

a total throughput of up to 4 t/h (higher throughputs

are possible with this extruder), is equipped with

2 synchronous motors, ensuring a short overall length. Torque fluctuations are measured very precisely, enabling exact control of PET regrind feeding into the extruder.

At a glance

- Gentle processing of PET regrind

- Very low specific energy input (kWh/kg)

- Robust beveloid gearbox with optional condition monitoring

- Very short process unit with consistently low melt temperatures

In addition, NGR provides all the equipment for conveying pellets such as blower, pipes, cyclones and much more.

Technology

Efficiency through Conical Co-Rotating Twin-Screw Extrusion

The ECO-Twin technology combines maximum energy efficiency with gentle material processing. Thanks to its intelligent design, plastic regrind is processed precisely, stably, and with minimal friction.

The extruder drive is equipped with variable speed control, allowing the throughput of the system to be perfectly adapted to the respective processing requirements.

ECO-Twin 220 – 2 × 285 kW drive power: up to 4,000 kg/h

ECO-Twin 220 – 2 × 325 kW drive power: up to 5,000 kg/h

Throughput values as specified.

ECO-Twin 220

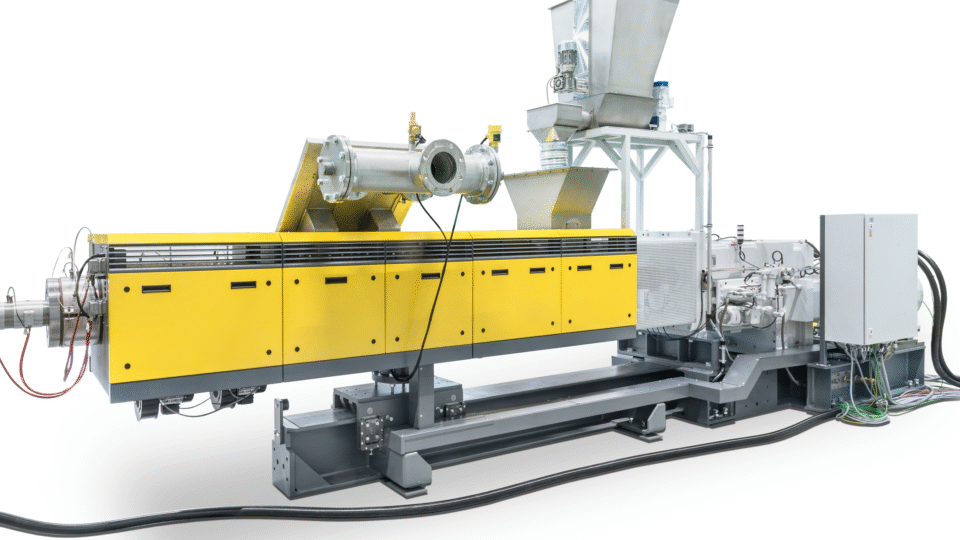

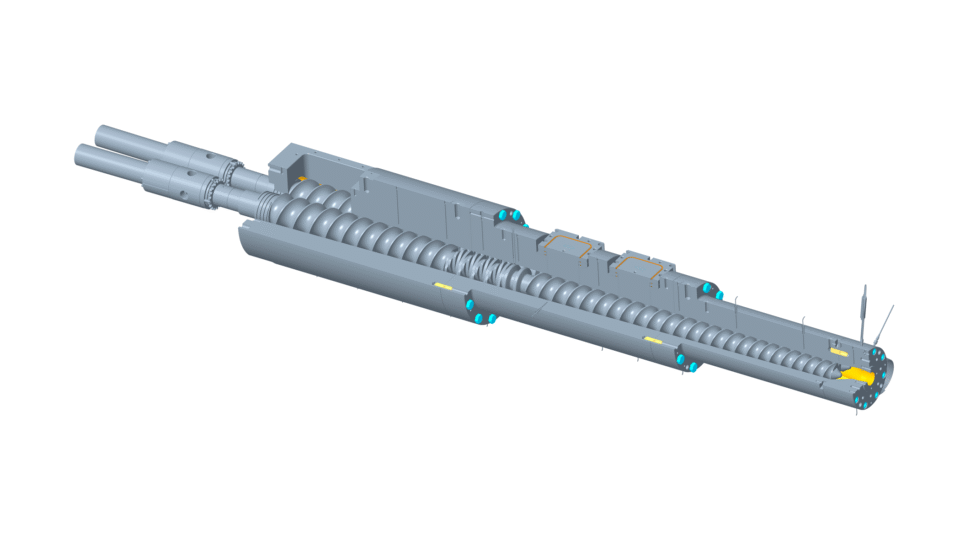

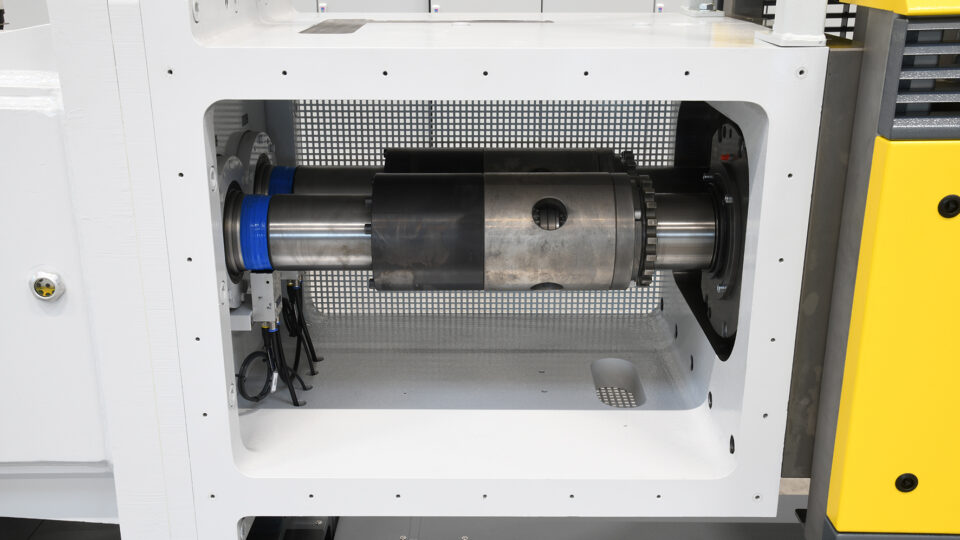

Processing Unit

With the conical co-rotating processing unit, the design follows the natural physical principle of a processing operation: large surfaces and high circumferential speeds in the feed zone to transfer energy into the material, and small surfaces with low circumferential speeds in the discharge zone with minimal friction and dissipation. As a result, the ECO-Twin ensures particularly gentle processing of plastic regrind with low bulk density.

ECO-Twin 220

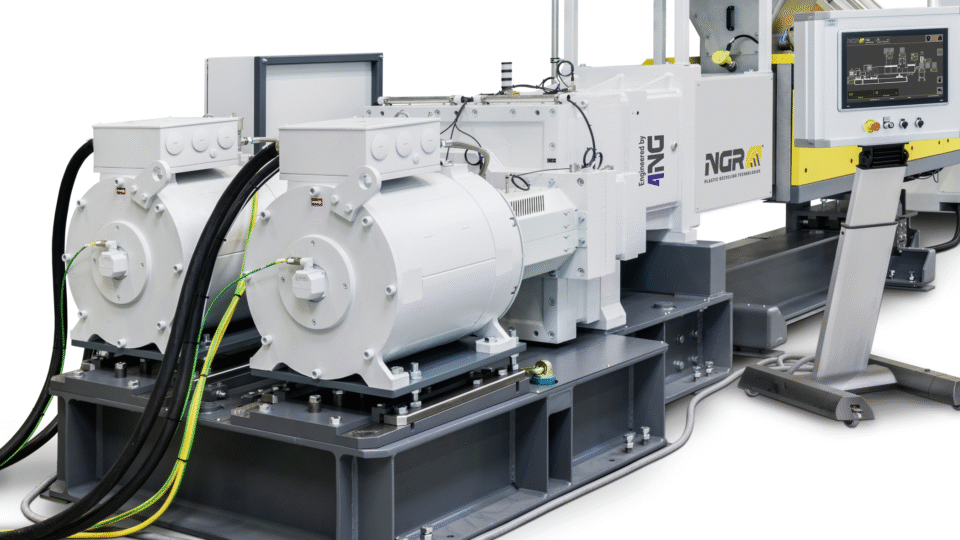

Gearbox & Extruder Drive

The drive consists of a compact beveloid gearbox with conically designed output gears. The shaft spacing has been selected to allow the transmission of extremely high torque, enabling high performance even at low rotational speeds.

An optional monitoring system supervises oil condition, lubrication, cooling, speed, and vibrations. The targeted circulation lubrication requires only small amounts of oil, reducing maintenance costs.

Two synchronous motors shorten the overall length and allow precise control of dosing by accurately detecting torque fluctuations. This ensures the extruder runs with high stability, constant energy input, and well-regulated, high throughput.

ECO-Twin 220

Cylinder

The cylinder is connected to the gearbox via a coupling housing that dampens mechanical vibrations. The screws are supported in the flange area, which increases stability. The cylinder can be swiveled open on both sides, allowing space-saving removal of the screws – ideal for systems used in the production of semi-finished products such as films.

ECO-Twin 220

HMI Display

The HMI of the ECO-Twin is mounted “mobile” on a wheeled base. A 21.5” screen with a clearly structured interface ensures very operator-friendly system control. The control system is based on a Siemens S7 PLC: CPU 1515F. The ergonomically designed interface allows recipes to be managed with ease. Different access levels with password protection ensure that only authorized personnel can make critical adjustments.

ECO-Twin 220

Feeding of Additives

In the ECO-Twin, additives are fed directly into the extruder’s feed opening. Both dosing of liquid additives and feeding in granular form are possible.

ECO-Twin 220

Alarm / Operating Indicator

Whenever the machine requires attention, it reliably informs the operator through visual signals and acoustic warning messages. This ensures that processes are continuously monitored and any deviations are detected immediately.

Add-Ons

Venting

Venting

ECO-Twin 220 venting

ECO-Twin 220 venting

The two process-technically connected degassing ports are equipped with generously dimensioned degassing attachments, which can be connected via a flange connection to a high-performance vacuum system. The size of the connection flange is 160 mm (Flange Type 01 PM16 / DN 150). The entire degassing system of the extruder is designed for a vacuum level of ≤ 1 mbar.

Support

Our all-round service – satisfaction included

Excellent technology calls for excellent service. Our 100% commitment to flawless service ensures maximal cost efficiency and minimal downtime.

Our services

- Service hubs for the fastest possible processing of all maintenance and repair work

- Spare parts centers for flexible responses to strong markets

- High spare parts availability thanks to particularly high stock levels in Europe and North America

- Worldwide extruder screw production for short-term production or repairs

- Starter and spare parts packages for every new machine

NGR Applications & Solutions

[5 MB]