F:GRAN

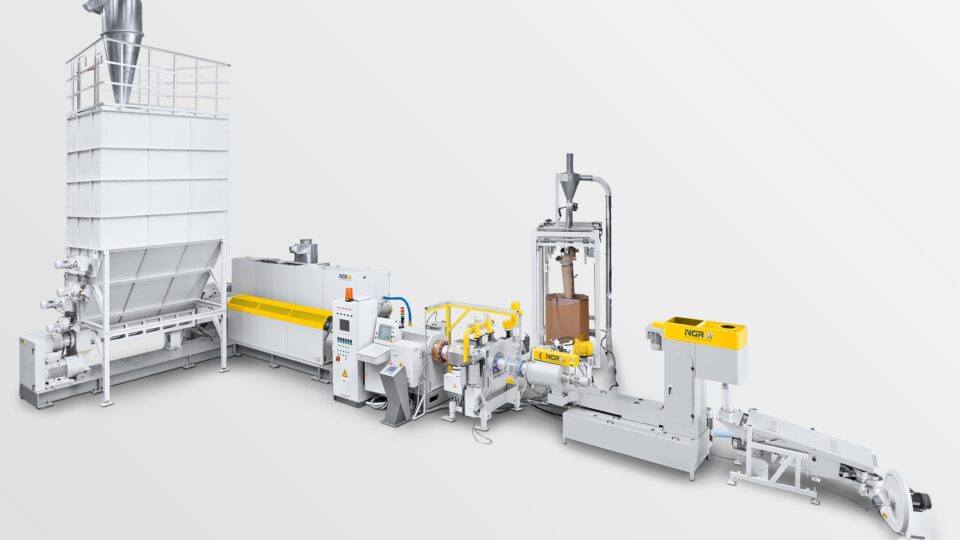

The efficiency star for pre-shredded material

Thanks to a wide range of various system sizes, F:GRAN can be implemented as a precise fit. Together with its significantly increased energy efficiency, this recycling technology is doubly cost-effective.

Description

In recycling of ground up plastics, predominantly from plastic washing sys- tems, there is no better choice than the F:GRAN. Flakes, even of varying size, are processed at a consistently high throughput rate.

F:GRAN is distinguished by its efficient material handling. The flakes to be processed are continuously circulated by rotors in a storage silo measuring up to 30 m3. This prevents problems caused by bridging from the beginning.

At a glance

- Processing regrind and film flakes

- Output rate up to 2.500 kg/h (5,500 lbs/h) depending on type

- Switching on and off by a single push button

- Simple, stable process

- Storage silo up to 30 m3 for material buffer

* Output values for LDPE according to NGR company standard, depending on material and quality. Depending on the application, we naturally can also integrate common piston screen changers.

Technology

The operating principle of F:GRAN

In the anti-bridging silo, rotors keep the plastic flakes in motion. This prevents the flakes from bridging and ensures flowability.

In the transition area between the flake conveyor and the extruder input, the feeding screw acts like a feeder. The flakes are gently transported continuously from the large-dimensioned feeder screw into the extruder. This arrangement facilitates the processing of flakes of different sizes (the flake size is of minor importance). The pressure on the plastic flakes increases steadily as they enter the extruder intake, in order to achieve high throughput rates.

All the components are positioned in close proximity to prevent oxidation of the material and to make optimal use of heat from the shredding process.

Automatic feeder screw control

The feeder screw is automatically activated depending on the utilization of the extruder capacity. This ensures an optimized throughput without operator interference saving on labour costs.

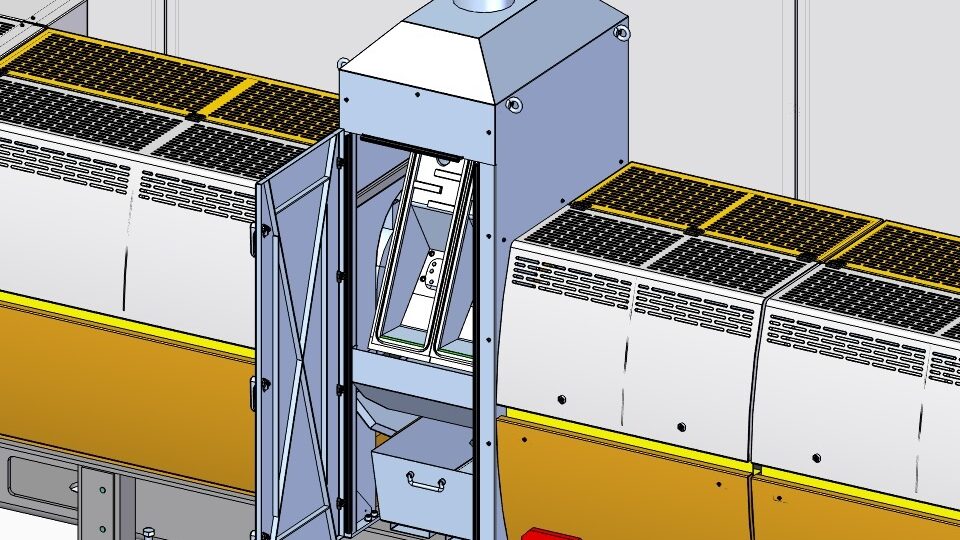

Anti-bridging silo

The anti-bridging silo is used to store the plastic flakes and is equipped with rotors to prevent the flakes from bridging. Located directly over the feeder screw, the anti-bridging silo ensures a continuous supply of flakes.

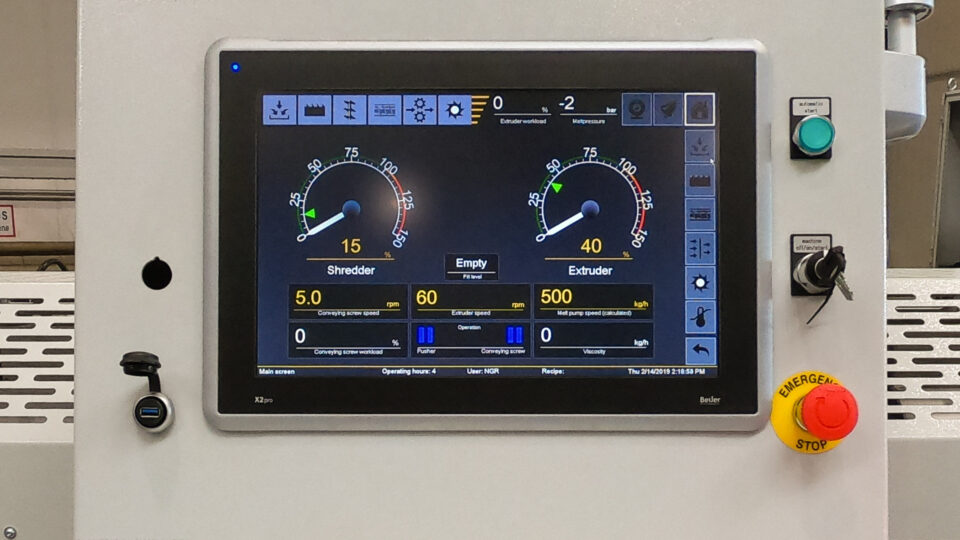

One-button automatic ON/OFF control

The control system provides for smooth start-up of equipment components. Restart after unplanned shutdown in less than two minutes with full hopper and full extruder.

Dump and run operation

The material level in the anti-bridging silo is constantly measured and the feed is regulated accordingly. Discontinuous filling of the anti-bridging silo is possible – the NGR control unit does the rest .

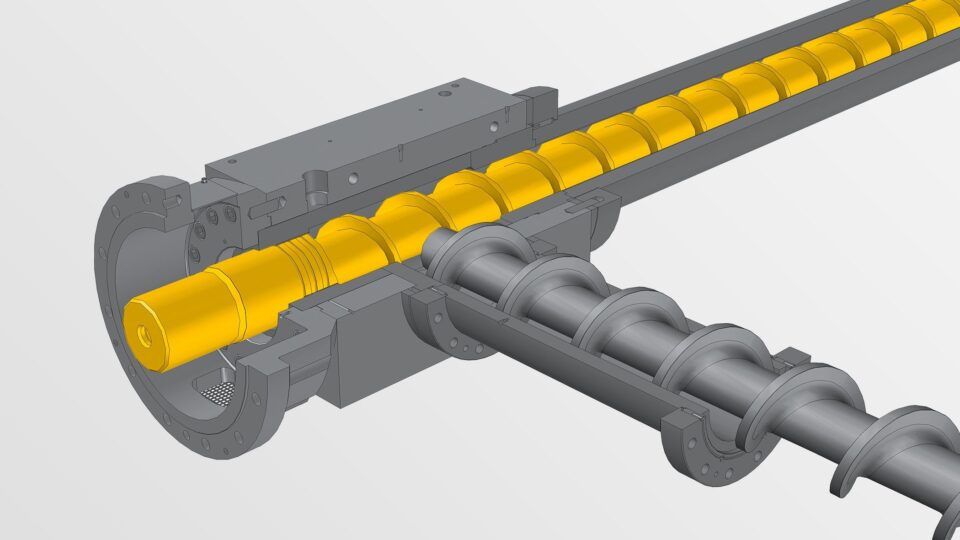

Extruder screw

Extruder screw

Specially developed for the challenges of recycling, the universal extruder screws provide optimum melt homogeneity and process material efficiently with minimal loss of physical properties. For special requirements, our expert NGR engineers develop custom-tailored screw geometries.

Control unit

Control unit

All equipment functions from feeding to pelletizing are controlled automatically from the easy-to-read NGR touchscreen. Recipes are managed in the operator control unit, which increases traceability, provides ease of use, and ensures equipment parameters are set properly.

High-quality pellets

Pellet size

In addition to high quality, the uniform pellet size also provides for homogeneous mixture in new material. NGR thus plays an indirect role in ensuring consistent quality in the final product.

Add-Ons

Feed-in

Degassing

Pelletization

Filter

Test equipment

Feed-in

Conveyor belt

Conveyor belt

The conveyor belt transports the feed material through a metal detector into the feed hopper. The belt is stopped automatically, if metallic matter is detected in order to remove it.

Dosing unit

Dosing unit

Additives such as color pigments, CaCo3, compatibilizers can be added to the material flow in a process-controlled manner. Dosing systems for pellet and/or powdered additives are available.

Degassing

Single venting

Single venting

Designed for light printing and low humidity. The vacuum degassing system includes a vacuum pump and is connected to two venting ports on the extruder.

Double venting

Double venting

Designed for plastics printed, for example, on all surfaces and/or moist plastics. The simple venting unit can be supplemented by another modular unit with two venting openings and an additional vacuum pump.

Heavy duty vacuum pump

High-performance vacuum

In addition to the modular venting unit, a combination of water ring pump and high-performance vacuum pump runs in order to increase the vacuum performance (e.g. PET processing).

Combined venting

Combined venting

For damp materials, e.g. after washing, combined venting unit is used, which consists of an atmospheric and vacuum degassing unit.

Vacuum pump with closed water circuit

Vacuum pump with closed water circuit

Each venting combination can be equipped with a closed water circuit. The fresh water consumption at the vacuum pump is thereby reduced significantly.

Pelletization

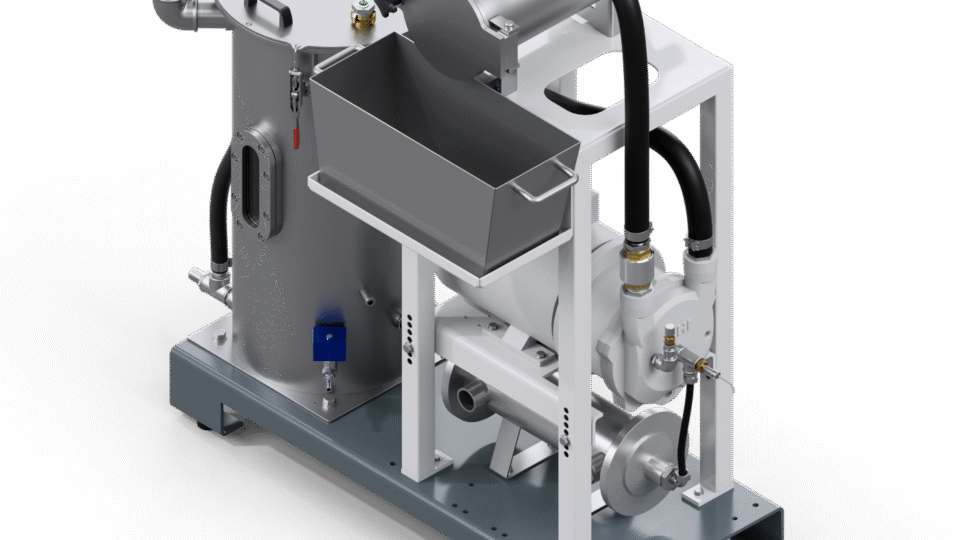

HD pelletizer

Hot-die Waterring Pelletizer (HD)

For thermoplastics with a higher viscosity. The melt exits through the wear-resistant die plate, and is knocked off by the pelletizer blades. The pellets cooled in the water ring are flushed out, dried in the centrifuge and discharged. By adjusting the blade pressure, pelletizer blades provide a long service life; replacement is quick and easy.

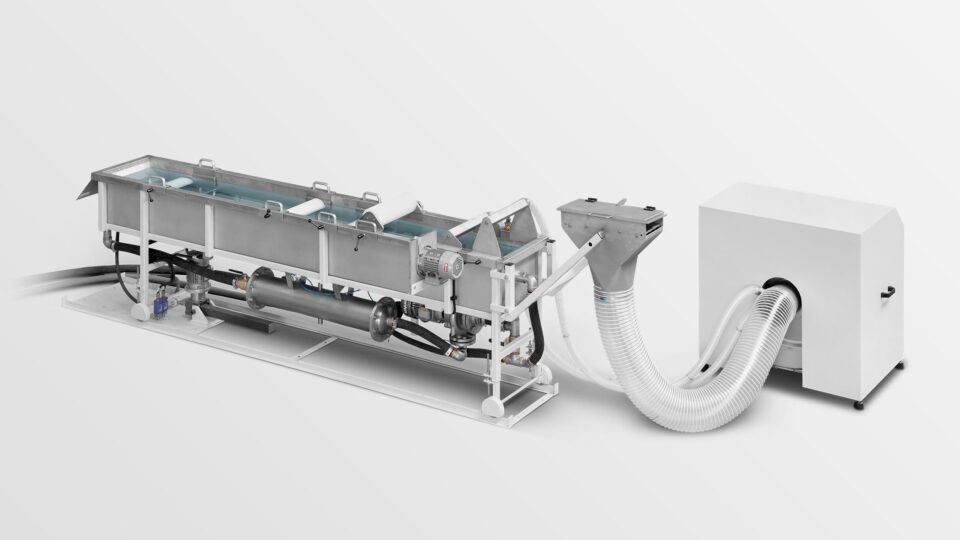

Strand pelletizer

Strand pelletizer (SP)

For low-viscosity melts. The melt emerges from strand nozzles, is cooled in a water bath, dried by means of a fan and cut to the desired length in the pelletizer. The result is cylindrical, dust-free pellets with excellent mixing properties.

Automatic strand pelletizer

Automatic strand pelletizer (A-SP)

In addition to the benefits of the SP, the A-SP option offers the added convenience of fully automated start-up. The strands are transported automatically by a water slide to the pelletizer, and the pellets are dried in a centrifuge.

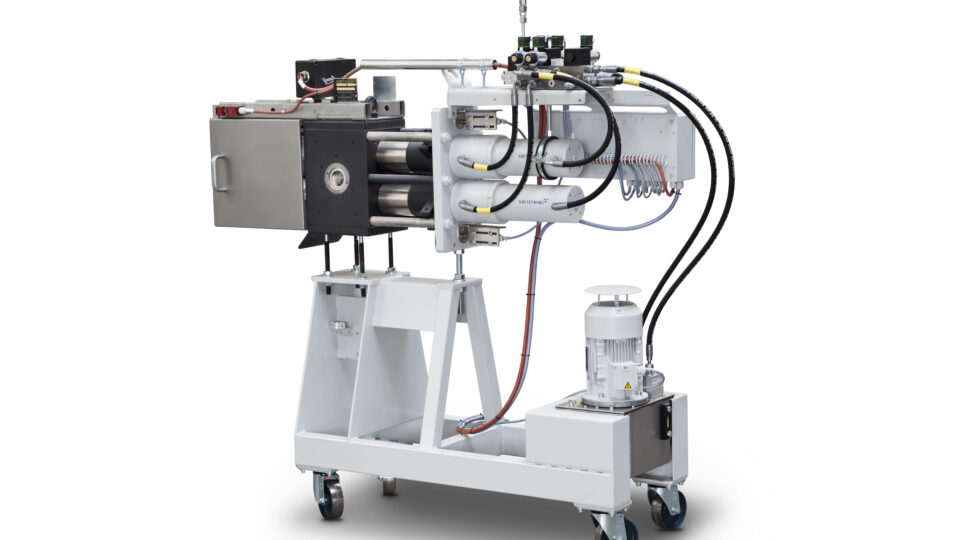

Under Water Pelletizer

Underwater pelletizer (UWP)

For difficult-to-process (e.g. sticky) polymers or thermoplastics with a very high melt flow index. The melt emerges from the die plate and is knocked off by the pelletizer blades. The whole process takes place under water. In the centrifuge, the pellets are separated from the process water and dried.

Filter

Double piston screen changer

Double-piston screen changer

For light impurities. The hydraulically operated double-piston screen changer allows continuous filtration of the melt. This allows a screen change without process shutdown.

Backflush screen changer

Back-flush screen changer

For heavily contaminated materials. The hydraulically operated double-piston screen changer filters the melt in a process-controlled and continuous manner. The integrated backwash device automatically cleans the screens. The number of back-flushes and the related service life of the screens depend on the degree of contamination of the material.

4K Backflush screen changer

4K back-flush filtration

For heavily contaminated materials. In contrast to the standard backflush screen changer with 2 screen cavities, this system is equipped with 4 screen cavities. The double filtration surface with the same frame size results in a longer filter life.

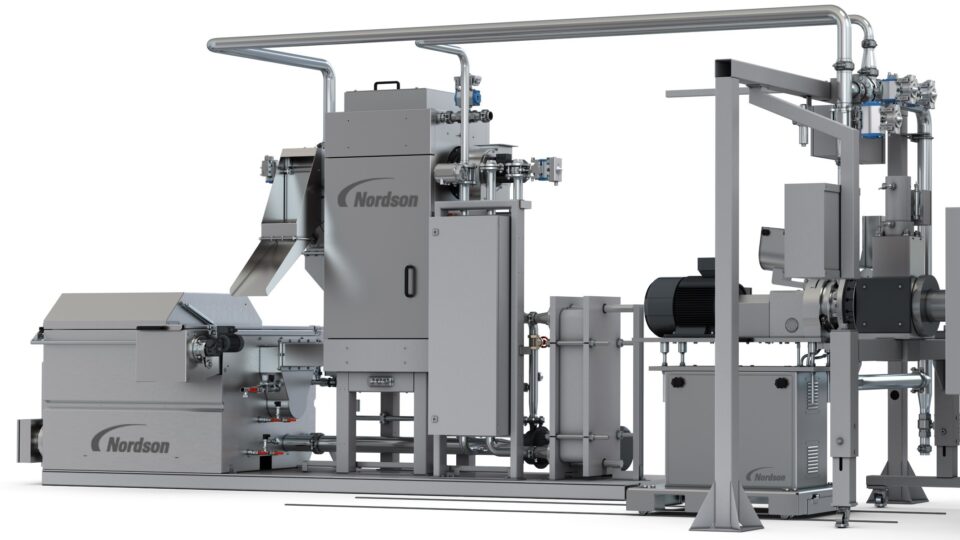

Automatic band melt filter

Band melt filter

For high contamination at high throughput rates. With the lowest melt losses and low filter costs, fully automatic operation ensures excellent filtration results. It is used particularly for post-consumer plastics.

High-performance melt filter

High-performance melt filter

The continuous melt filters in the ERF series are suitable for a wide range of moderate and highly contaminated polymers and provides a pressure constant operation, long screen lifes, very low melt losses and a compact design. By the permanently rotating filter drum foreign particles are being constantly and effectively removed, depending on the application ERF melt filters enables throughputs from 150 to 10,000 kg/h.

Test equipment

Flow scale

Flow scale

The throughput scale is integrated in the machine control system and displays the current production output in kg/h (lbs/hr). The data can be logged in a BDE system.

Gas control unit

Gas control unit

This unit provides quality control by continuously measuring pellet density. Based on preset parameters, the unit determines whether to switch the gates to the second choice or to scrap when this value falls below a setpoint. Monitoring is inline and integrated continuously in the production process.

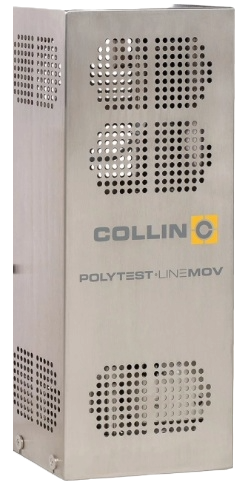

Online Viscometer

Online Viscometer

For continuous melt viscosity measurement. Melt is taken from the production extruder, the viscosity is measured, and then the melt is returned to the extruder.

Based on the differential pressure across the capillary, the viscosity of the material (IV value, MVR) is determined by means of a stored recipe.

Material samples

Gallery

Images

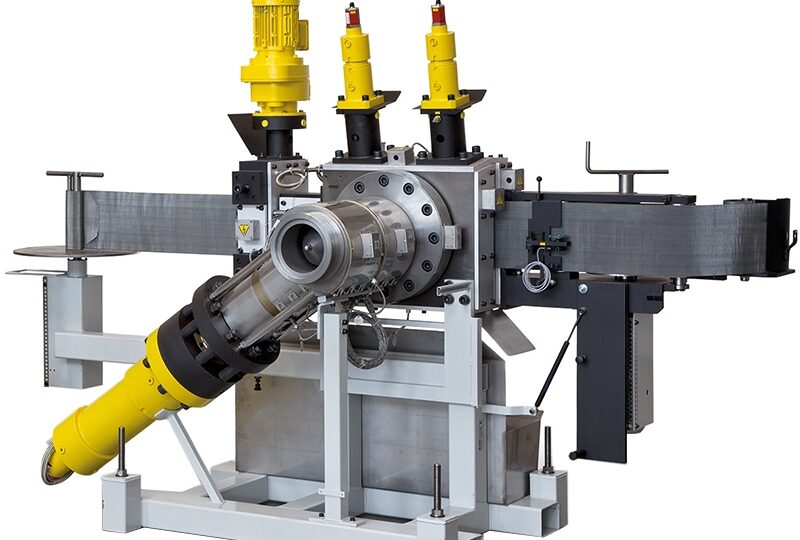

The solidly designed feeder screw transports the plastic flakes to the extruder. Before the extruder intake, pressure is continuously built up on the flakes.

In this section, the feeder screw acts like a feeder, which supports the feeding into the extruder intake and thus ensures high throughput rates.

Testimonials

NGR’s response time and service driven partnership sets a standard unmatched in the industry.

Phillip Goldberg, President

Columbia Recycling, USA

Support

Our all-round service – satisfaction included

Excellent technology calls for excellent service. Our 100% commitment to flawless service ensures maximal cost efficiency and minimal downtime.

Our services

- Service hubs for the fastest possible processing of all maintenance and repair work

- Spare parts centers for flexible responses to strong markets

- High spare parts availability thanks to particularly high stock levels in Europe and North America

- Worldwide extruder screw production for short-term production or repairs

- Starter and spare parts packages for every new machine

NGR Applications & Solutions

[5 MB]