Pelletizing

Due to the modular construction of the recycling systems, different pelletizer systems can be used in a process-controlled manner, depending on the plastic processed.

Hot-die Waterring Pelletizer (HD)

For thermoplastics with a higher viscosity. The melt exits through the wear-resistant die plate, and is knocked off by the pelletizer blades. The pellets cooled in the water ring are flushed out, dried in the centrifuge and discharged. By adjusting the blade pressure, pelletizer blades provide a long service life; replacement is quick and easy.

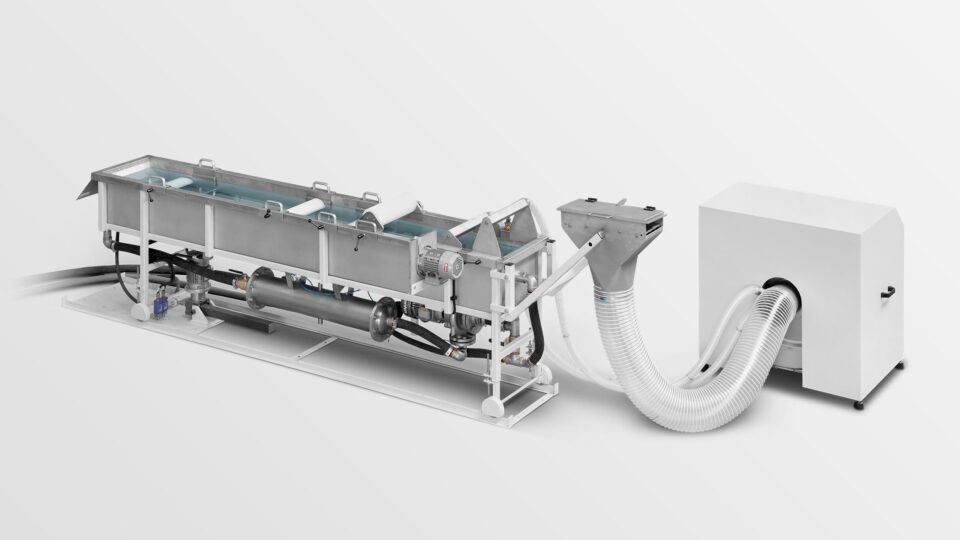

Strand pelletizer (SP)

For low-viscosity melts. The melt emerges from strand nozzles, is cooled in a water bath, dried by means of a fan and cut to the desired length in the pelletizer. The result is cylindrical, dust-free pellets with excellent mixing properties.

Automatic strand pelletizer (A-SP)

In addition to the benefits of the SP, the A-SP option offers the added convenience of fully automated start-up. The strands are transported automatically by a water slide to the pelletizer, and the pellets are dried in a centrifuge.

Hot die-air pelletizer

Specially designed for inline applications where water is not used. The melt exits through the wear-resistant die plate, and is knocked off by the pelletizer blades. The pellets are carried away in the air stream and cooled.

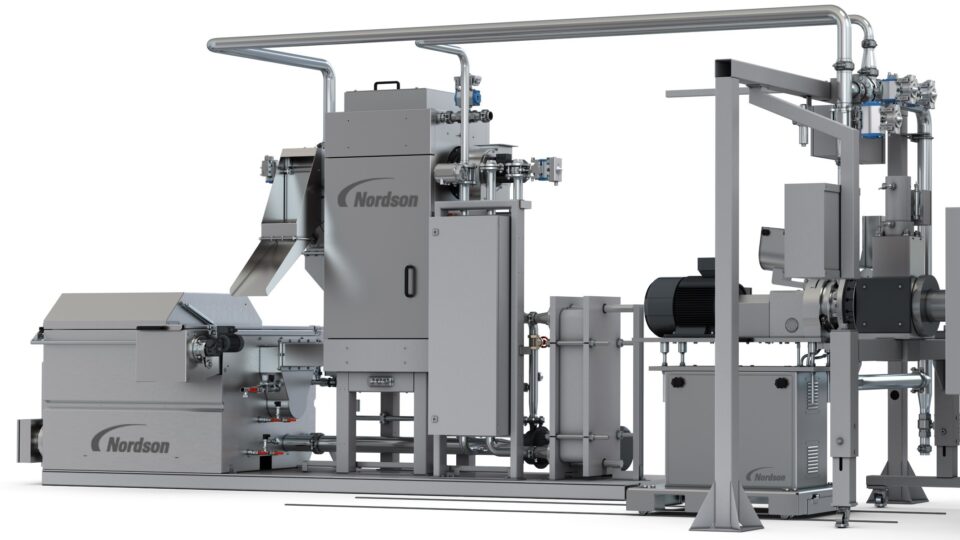

Underwater pelletizer (UWP)

For difficult-to-process (e.g. sticky) polymers or thermoplastics with a very high melt flow index. The melt emerges from the die plate and is knocked off by the pelletizer blades. The whole process takes place under water. In the centrifuge, the pellets are separated from the process water and dried.