Two Technologies – One Goal: Perfect PET Recycling

6. October 2025

ECO-Twin & LSP: The New Benchmark in Bottle-to-Bottle Recycling

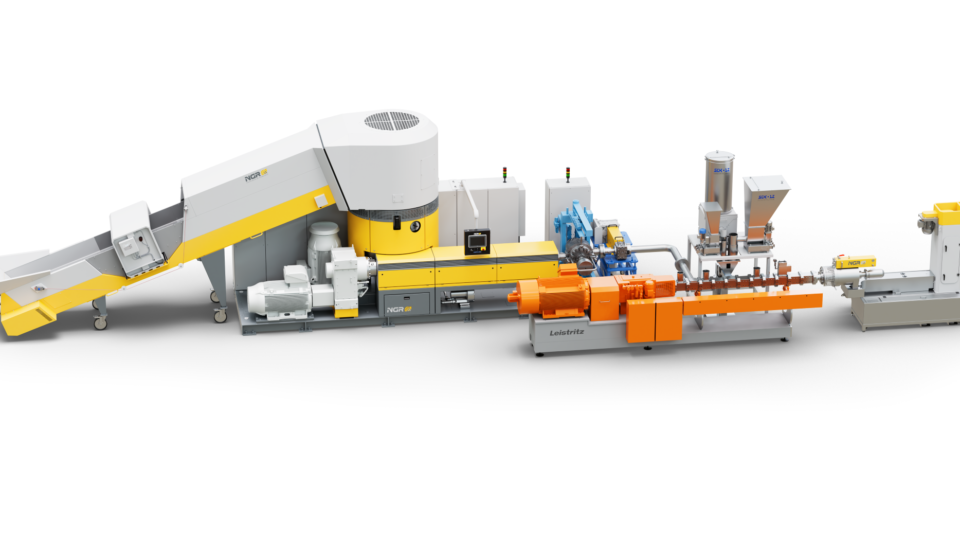

By combining the new ECO-Twin extruder with the proven LSP (Liquid State Polycondensation) technology, NGR sets new standards in industrial PET processing. These two systems complement each other perfectly, forming a powerful solution for the highest demands in quality, efficiency, and sustainability in bottle-to-bottle recycling.

ECO-Twin: Efficiency in Perfection

The conical co-rotating ECO-Twin extruder impresses with a particularly gentle melting process while providing highly effective melt degassing. The physical and rheological requirements for an extruder are met almost perfectly.

“The ECO-Twin 220 is a true milestone. The combination of low melt temperature, high degassing performance, and minimal energy consumption makes it the ideal solution for demanding PET recycling.” – Stefan Lehner, Head of Product Management PCR at NGR.

A key feature of the new ECO-Twin extruder is its exceptionally low specific energy input – a decisive advantage in times of rising energy costs and increasing sustainability requirements. At the same time, the gentle processing of PET regrind ensures high material quality and minimized thermal stress.

At the core of the machine is a robust gearbox based on Beveloid- technology, ensuring smooth operation and long service life. Optionally, it can be equipped with a condition monitoring system to enable predictive maintenance and enhance operational reliability.

LSP Technology: Maximum Purity and Safety

The LSP bottle-to-bottle system processes washed bottle flakes directly in the molten state. The intrinsic viscosity (iV) is continuously and fully automatically controlled – a unique feature in the market.

“With P:REACT, we achieve a decontamination performance far beyond what is possible with conventional SSP – and that with a significantly more compact design and higher energy efficiency.”– David Hehenberger, Head of Product Management “PET” at NGR.

NGR’s LSP bottle-to-bottle technology stands out with a range of advantages that clearly differentiate it from traditional SSP systems. Particularly noteworthy is the exceptionally high decontamination performance, which reliably removes even health-relevant substances such as limonene, benzene, and toluene. This ensures the highest standards of product safety and quality.

Another key advantage is its 100% food-grade capability, confirmed by EFSA and FDA approval. The direct processing of PET flakes in the molten state ensures maximum efficiency while reducing energy consumption and system complexity.

The integrated automatic iV control guarantees consistent mechanical properties of the final product – regardless of fluctuations in the input material. This precise control is complemented by a modern SCADA system, which enables intuitive operation, comprehensive visualization, and maximum transparency during operation.

Strong Together: Throughput up to 4,000 kg/h

In combination with the ECO-Twin extruder, the LSP system achieves an impressive total throughput of up to 4,000 kg/h – a new milestone in industrial PET processing. Its compact design and low energy consumption make the system particularly attractive for modern production environments.

Proven and Trusted

With over 60 reference installations worldwide, including 30 in food-grade applications, LSP technology brings extensive practical experience. It is not only a technological milestone but also a clear statement for the future of the circular economy.

Conclusion

The combination of ECO-Twin and LSP is the answer to the growing demands in PET recycling. It stands for top quality, maximum efficiency, and uncompromising safety – and defines the new standard in bottle-to-bottle recycling.