NGR scores big with artificial turf reprocessing

Imagining the world’s top sports without artificial turf is virtually impossible today. The company FieldTurf is a global player in this segment, providing sustainable production alongside high performance and extreme durability.

FieldTurf,part of the Tarkett Group, is a global market leader in innovative and sustainable solutions for flooring and sports surfaces. The FieldTurf story started in 1988 with the introduction of a synthetic grass system for tennis courts and an artificial grass surface for golf courses. Turf systems for other sports quickly followed. The goal was always the same: improving safety for athletes & allowing the best possible performance together with excellent durability. Today, sports arenas in more than 100 countries around the world use FieldTurf artificial grass systems.

The high score for the NGR S:GRAN

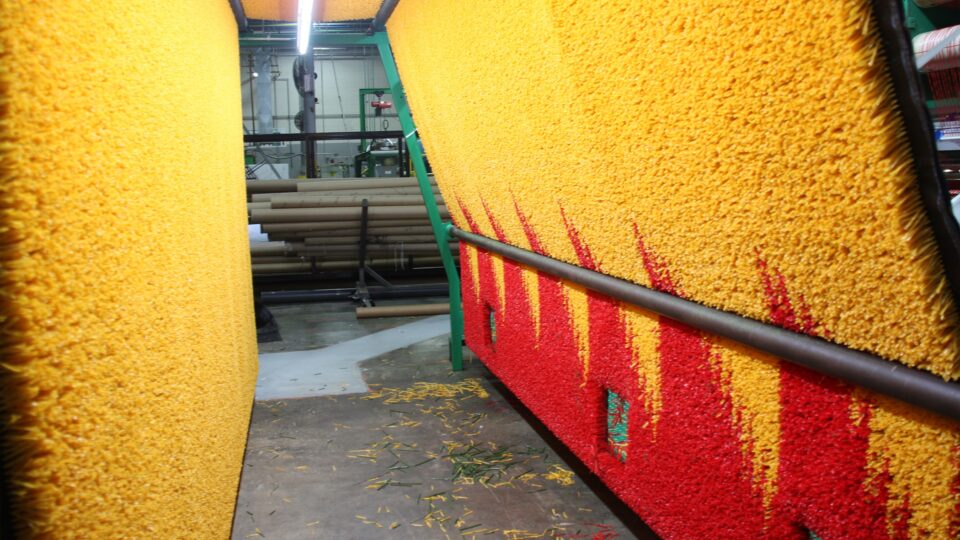

FieldTurf has been using an S:GRAN 065-70 V HD machine from the Austrian company NGR, Next Generation Recycling Machines, for the repelletizing of its production waste since 2016. Approximately one million pounds of scrap are repelletized per year at present, with the capability of up to three million pounds if needed. Nicolas Aumonier, Innovations Lab Manager at FieldTurf, explains, “Before we bought the machine, our plastic waste ended up in a landfill. That approach did not fit our sustainable thinking. But first we had to test out how recycled material would work for our artificial turf.” It turns out they are a winning combination. The reprocessed pellets are currently used in the production of [for] two products: Coolplay, an artificial turf with a woven backing, and VersaTile, a special underlay for shock damping and drainage. And why choose NGR? Aumonier notes, “Other recycling machines usually consist of multi-stage machines that generate a lot of dust. NGR machines, on the other hand, use a shredder-feeder-extruder combination that is perfect for our purposes.”

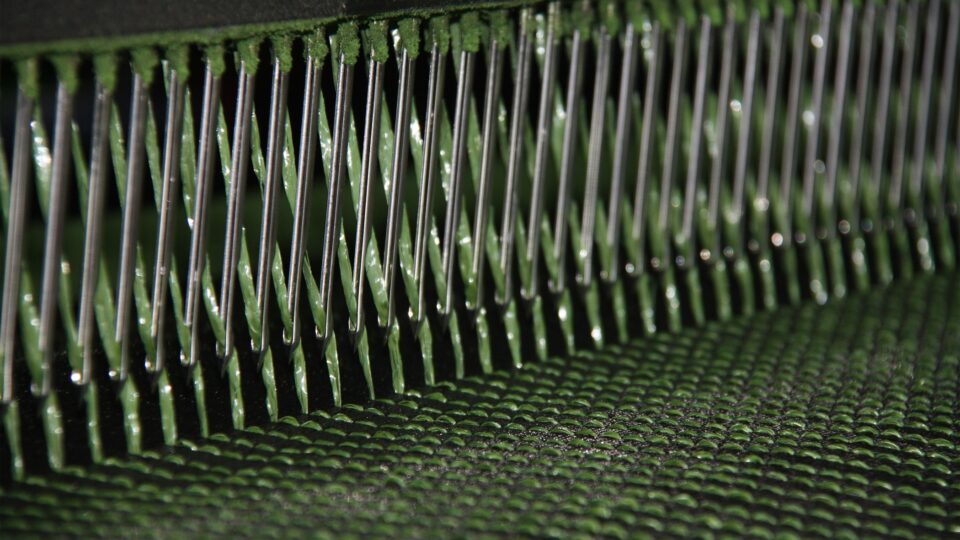

In the S:GRAN “One-Step” recycling machine used by FieldTurf, the artificial is shredded and conveyed directly into the extruder in a single continuous process. The single-shaft shredder integrated into the system has a low-speed cutter with a rugged design for reliable operation over the long life of the cutting blades.

NGR is an international company that has been producing plastics recycling machines for more than 20 years—the 1000th system was delivered to a customer in late 2017.